Microstrip Coupler

Introduction

This is a microstrip coupler designed over a 20 mil RO4003C using a single section of coupled microstrip lines.

The Branch-Line coupler is one of the easiest couplers to design, and it is very common and well known in the literature. It consists of four λ/4 transmission lines: the series lines are Z₀/√2 Ω and the shunt lines are Z₀ Ω.

Features

Simple design

Easy to fabricate in microstrip

Good port isolation

Relatively wideband

All ports are matched simultaneously

Warning

High couplings (< 10 dB) require very small gaps.

The coupling depends a lot on the gap, so manufacturing tolerances may have a significant on it.

Large size at low frequencies

Specifications

Feature |

Value |

|---|---|

Band |

[1500, 2800] MHz |

Insertion Loss |

0.3 ± 0.1 dB |

Coupling |

15.5 ± 0.5 dB |

Return Loss |

<-20 dB |

Isolation |

>16 dB |

Design Procedure

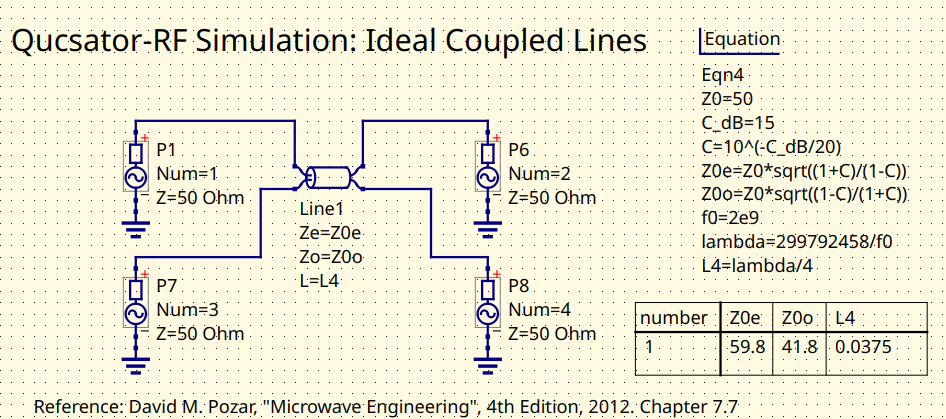

1. Ideal Transmission Line Implementation

As a first approach, the coupler is designed with ideal transmission lines by using the design equations. This can be done in Qucs-S using the Qucsator-RF backend.

Coupler schematic with ideal transmission lines

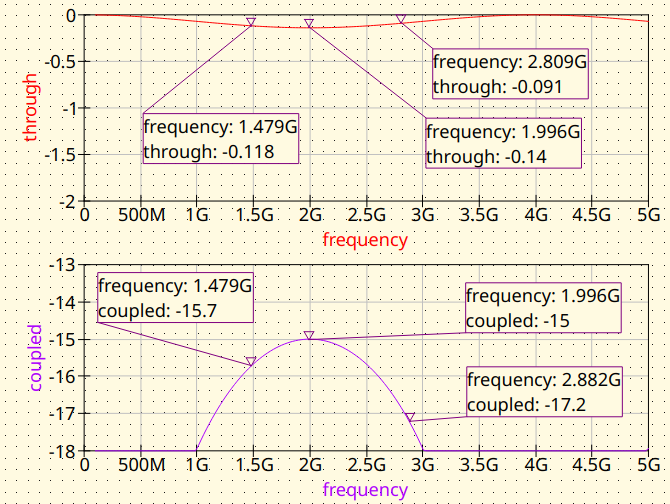

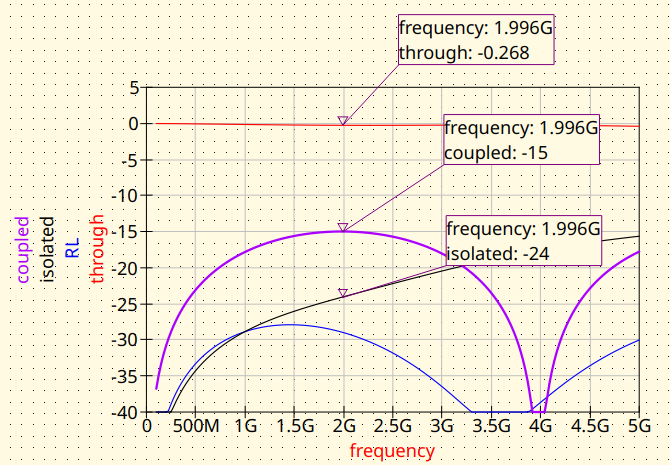

Coupler with ideal transmission lines. Magnitude response

2. Microstrip (MS) Line Implementation

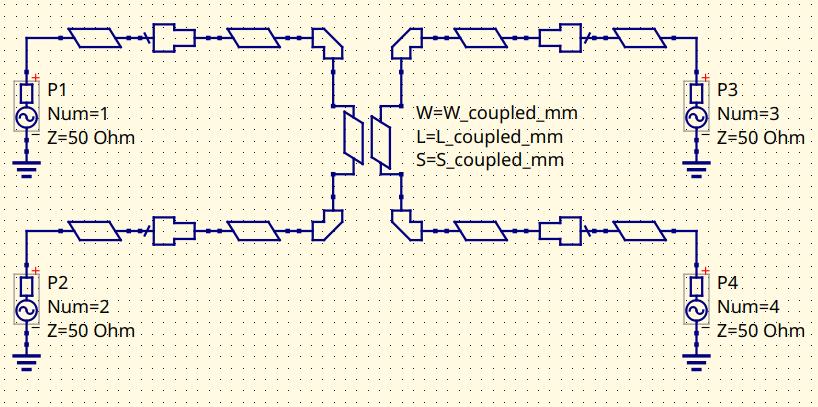

The ideal transmission lines are replaced by microstrip transmission lines. The synthesis can be done with the Transmission Line tool from Qucs-S.

MS Coupler using Qucsator-RF models. Schematic

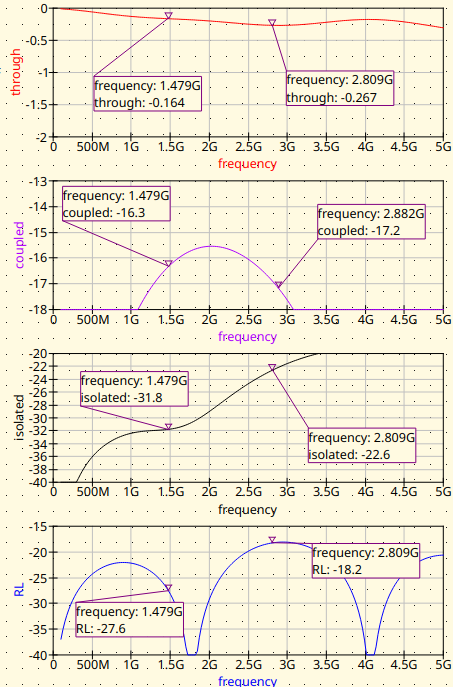

MS Coupler using Qucsator-RF models. Magnitude response

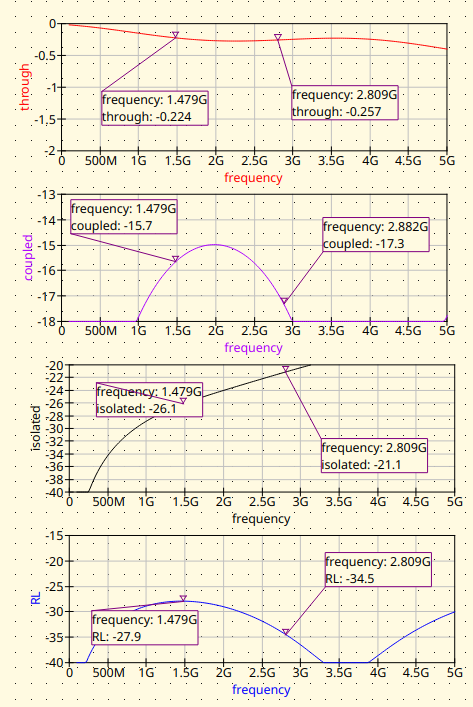

MS Coupler using Qucsator-RF models. Magnitude response (detail)

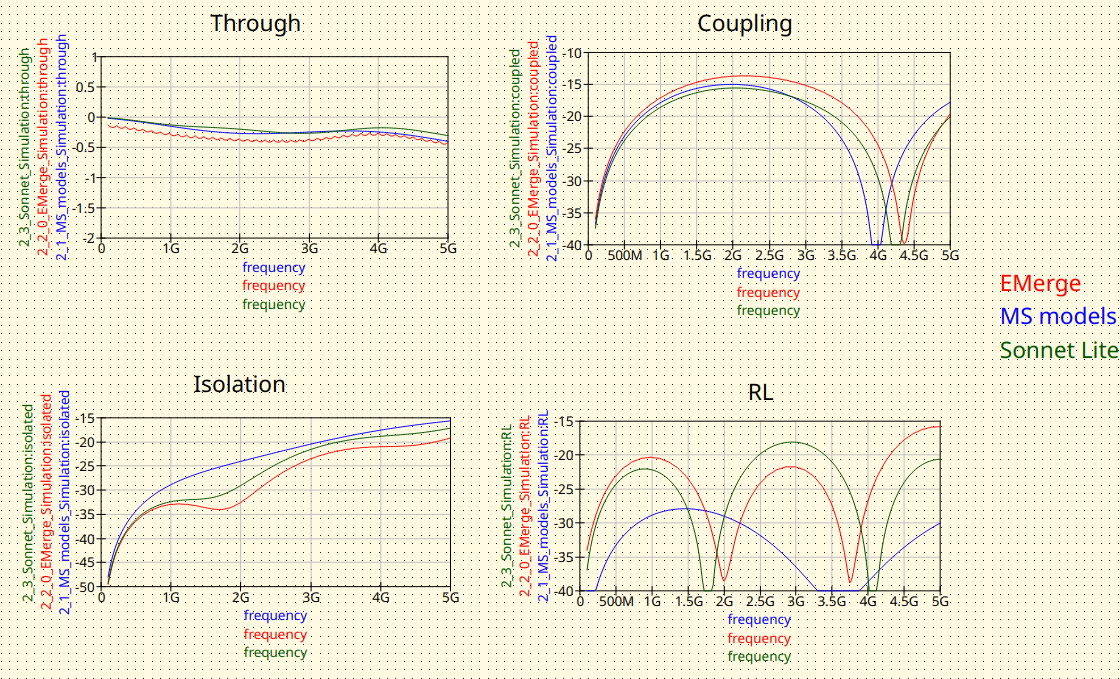

3. EM Simulation

In order to get more accurate results, it’s a good practice to simulate the design using EM tools. In this cases, two free tools are being considered:

Sonnet Lite. Free, runs well on Wine.

EMerge FEM & open-source. Very nice project. 🔥Check it out!🔥

3.1 Sonnet Line

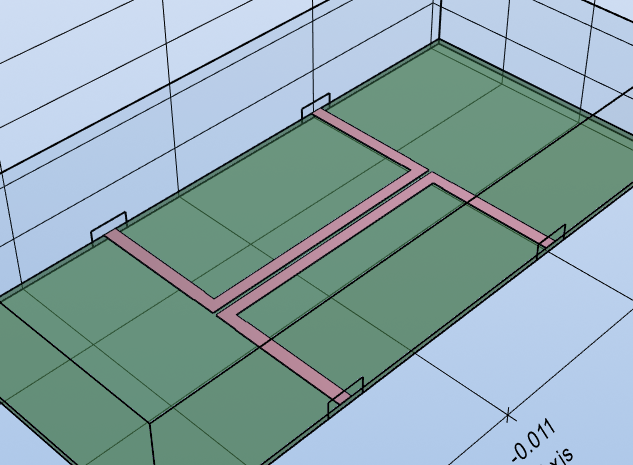

The model is build on the GUI of Sonnet Lite.

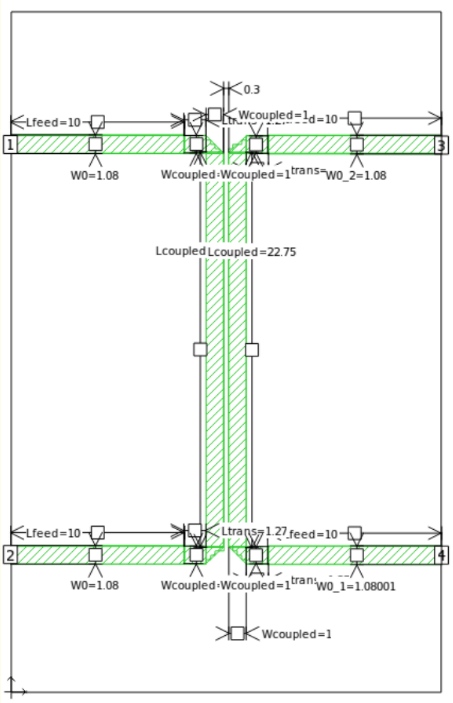

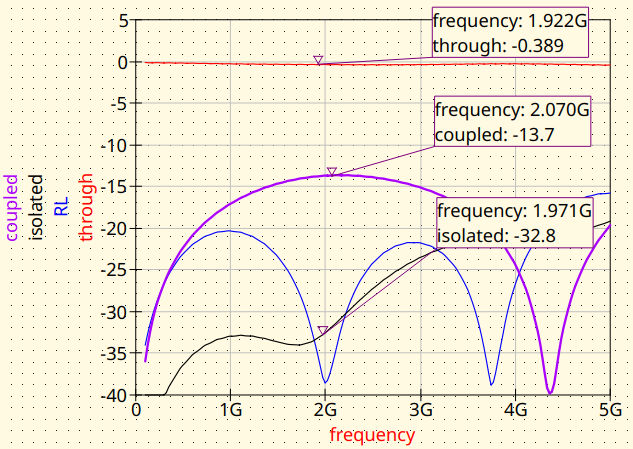

MS Coupler Sonnet Lite modelling

The results obtained were the following:

3.2 EMerge

The model is build on a Python script in a very convenient way.

import subprocess # Used to run the post-processing script

import emerge as em

import numpy as np

import time

from datetime import datetime

# ---------------------------------------------------------------------------

# PROJECT NAME

# ---------------------------------------------------------------------------

project_name = "Coupler_15dB"

# Constants

cm = 0.01

mm = 0.001

mil = 0.0254 * mm

um = 0.000001

MHz = 1e6

PI = np.pi

# ---------------------------------------------------------------------------

# Substrate properties

# ---------------------------------------------------------------------------

er = 3.55 # RO4003C relative permittivity

th = 0.508 # [mm] (20 mil) Substrate thickness

tand = 0.0029 # Substrate tand

# ---------------------------------------------------------------------------

# Center frequency

# ---------------------------------------------------------------------------

f0_MHz = 2000;

f0 = f0_MHz*MHz # centre frequency (Hz)

# ---------------------------------------------------------------------------

# Coupler circuital model parameters

# ---------------------------------------------------------------------------

W0 = 1.08 # [mm] Width for 50 ohm line in RO4003C

# Coupled line parameters for 15 dB coupler

L_coupled = 22.75 # [mm] Quarter wavelength at center frequency

W_coupled = 1.0 # [mm] Line width for coupled section

S_coupled = 0.3 # [mm] Gap between coupled lines

# Feed line lengths

L_feed = 10.0 # [mm] Lenght of the input/output feed lines

L_trans = L_feed / 10 # [mm] Length of the transition

Hair = 10 # [mm] Air box height

# ---------------------------------------------------------------------------

# Simulation setup

# ---------------------------------------------------------------------------

model = em.Simulation(project_name)

model.check_version("2.3.0")

# ---------------------------------------------------------------------------

# Frequency sweep

# ---------------------------------------------------------------------------

f_start = 100*MHz

f_stop = 5000*MHz

n_points = 40

# ---------------------------------------------------------------------------

# Material and PCB layouter

# ---------------------------------------------------------------------------

mat = em.Material(er=er, tand=tand, color="#488343", opacity=0.4)

pcb = em.geo.PCBNew(th, unit=mm, material=mat)

# ---------------------------------------------------------------------------

# Layout

# ---------------------------------------------------------------------------

# Upper trace: left feed → taper → 1st coupled stub entry

pcb.new(0, 0, W0, (1, 0))['p1'] \

.straight(L_feed) \

.straight(L_trans, W_coupled)

x_1st = L_feed + L_trans + W_coupled / 2

x_2nd = x_1st + W_coupled + S_coupled

y_top = W_coupled / 2

y_bot = y_top - L_coupled

# Parallel coupled lines (vertical)

pcb.new(x_1st, y_top, W_coupled, (0, -1)).straight(L_coupled)

pcb.new(x_2nd, y_top, W_coupled, (0, -1)).straight(L_coupled)

# Lower trace: left exit → taper → output feed (Port 2 – Through)

pcb.new(x_1st, y_bot + W_coupled / 2, W_coupled, (-1, 0)) \

.straight(W_coupled / 2) \

.straight(L_trans, W_coupled) \

.straight(L_feed, W0)['p2']

# Lower trace: right exit → taper → output feed (Port 4 – Isolated)

pcb.new(x_2nd, y_bot + W_coupled / 2, W_coupled, (1, 0)) \

.straight(W_coupled / 2) \

.straight(L_trans, W_coupled) \

.straight(L_feed, W0)['p4']

# Upper trace: right exit → taper → output feed (Port 3 – Coupled)

pcb.new(x_2nd, 0, W_coupled, (1, 0)) \

.straight(W_coupled / 2) \

.straight(L_trans, W_coupled) \

.straight(L_feed, W0)['p3']

# --- Compile traces ------------------------------------------------------

stripline = pcb.compile_paths(merge=True)

# --- PCB bounding box and substrate/air volumes -------------------------

pcb.determine_bounds(topmargin=15, bottommargin=15, leftmargin=0, rightmargin=0)

# ---------------------------------------------------------------------------

# Bounding box, dielectric and air

# ---------------------------------------------------------------------------

diel = pcb.generate_pcb(merge=True) # generate_pcb replaces gen_pcb

air = pcb.generate_air(Hair) # generate_air replaces gen_air

# ---------------------------------------------------------------------------

# Modal ports

# ---------------------------------------------------------------------------

p1 = pcb.modal_port(pcb['p1'], width_multiplier=3, height=2 * th) # Input

p2 = pcb.modal_port(pcb['p2'], width_multiplier=3, height=2 * th) # Through

p3 = pcb.modal_port(pcb['p3'], width_multiplier=3, height=2 * th) # Coupled

p4 = pcb.modal_port(pcb['p4'], width_multiplier=3, height=2 * th) # Isolated

# ---------------------------------------------------------------------------

# Solver settings

# ---------------------------------------------------------------------------

model.mw.set_resolution(0.25)

model.mw.set_frequency_range(f_start, f_stop, n_points)

# ---------------------------------------------------------------------------

# Assemble geometry

# ---------------------------------------------------------------------------

model.commit_geometry()

# ---------------------------------------------------------------------------

# Mesh refinement

# ---------------------------------------------------------------------------

model.mesher.set_boundary_size(stripline, 0.75 * mm)

# ---------------------------------------------------------------------------

# Mesh generation and visualisation

# ---------------------------------------------------------------------------

model.generate_mesh()

#model.view(plot_mesh=True)

model.view(plot_mesh=False)

# ---------------------------------------------------------------------------

# Boundary conditions

# ---------------------------------------------------------------------------

port1 = model.mw.bc.ModalPort(p1, 1, modetype='TEM') # Input

port2 = model.mw.bc.ModalPort(p2, 2, modetype='TEM') # Through

port3 = model.mw.bc.ModalPort(p3, 3, modetype='TEM') # Coupled

port4 = model.mw.bc.ModalPort(p4, 4, modetype='TEM') # Isolated

# ---------------------------------------------------------------------------

# Run solver

# ---------------------------------------------------------------------------

start_time = time.time()

data = model.mw.run_sweep(parallel=True, n_workers=8, frequency_groups=8)

run_time = (time.time() - start_time) / 60

print(f"Simulation completed in {run_time:.2f} minutes")

# ---------------------------------------------------------------------------

# Extract S-parameters (raw solver points)

# ---------------------------------------------------------------------------

grid = data.scalar.grid

f = grid.freq

S11 = grid.S(1, 1) # Input match

S21 = grid.S(2, 1) # Through

S31 = grid.S(3, 1) # Coupled

S41 = grid.S(4, 1) # Isolated

# ---------------------------------------------------------------------------

# Vector fitting — supersampled plot

# ---------------------------------------------------------------------------

n_supersamples = 2001

f_fit = np.linspace(f_start, f_stop, n_supersamples)

f_MHz = f_fit / 1e6 # Scale for displaying the graphs

S11_fit = grid.model_S(1, 1, f_fit)

S21_fit = grid.model_S(2, 1, f_fit)

S31_fit = grid.model_S(3, 1, f_fit)

S41_fit = grid.model_S(4, 1, f_fit)

phase_S21 = np.angle(S21_fit, deg=True) # direct output phase

phase_S31 = np.angle(S31_fit, deg=True) # coupled output phase

phase_diff = phase_S21 - phase_S31

# ---------------------------------------------------------------------------

# 3-D field visualisation at f0

# ---------------------------------------------------------------------------

field_mid = data.field.find(freq=f0)

model.display.add_object(diel, opacity=0.2)

model.display.add_object(stripline)

model.display.add_portmode(port1, k0=field_mid.k0)

model.display.add_portmode(port2, k0=field_mid.k0)

model.display.add_portmode(port3, k0=field_mid.k0)

model.display.add_portmode(port4, k0=field_mid.k0)

model.display.animate().add_field(

field_mid.cutplane(0.5 * mm, z=-0.5 * th * mm).scalar('Ez', 'complex'),

symmetrize=True,

)

model.display.show()

# --- Post-process and export Touchstone ----------------------------------

grid = data.scalar.grid

comments = [

f"--- {project_name} ---",

"Substrate: RO4003C",

f"h = {th} mm",

"Design parameters:",

f"W0 = {W0} mm",

f"L_coupled = {L_coupled} mm",

f"W_coupled = {W_coupled} mm",

f"S_coupled = {S_coupled} mm",

f"L_feed = {L_feed} mm",

f"L_trans = {L_trans} mm",

f"Air box height = {Hair} mm",

f"Run time = {run_time:.2f} min",

]

timestamp = datetime.now().strftime("%Y-%m-%d_%H-%M-%S")

file_name = project_name + "_EMerge_" + timestamp

grid.export_touchstone(file_name, custom_comments=comments)

# Save raw arrays for post-processing

np.savez(

project_name + "_data.npz",

f=f_fit, S11=S11_fit, S21=S21_fit, S31=S31_fit, S41=S41_fit, phase_diff=phase_diff,

)

subprocess.run(["python", "Coupler_post.py"], check=True)

This is how the model looks in the 3D viewer:

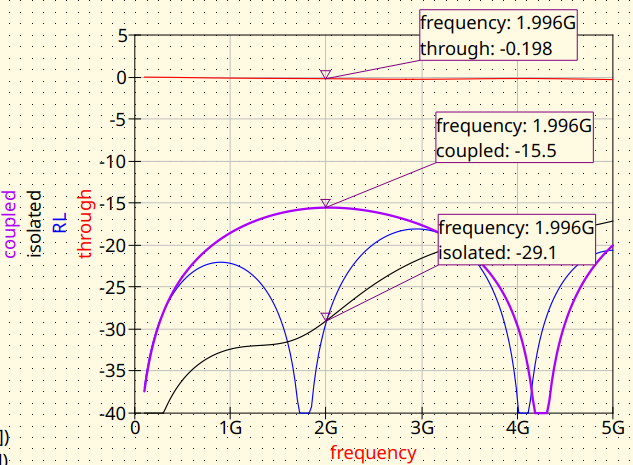

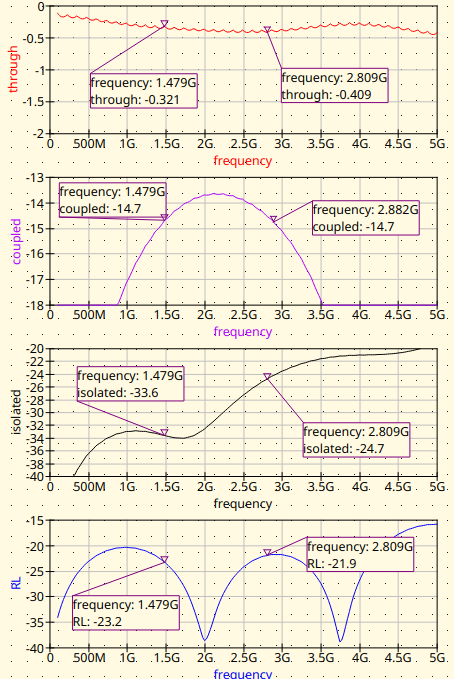

The results are the following:

Conclusion

As expected, the results obtained for the three simulators show slight differences. Which of them is the most accurate? It would be interesting to manufacture this coupler and compare this with data from a VNA.